It’s amazing how long modern belts and tensioners can last, but complacency can cost a lot of money and down-time, the experts warn

Trucks and their engine components really are a marvel of modern engineering.

Take the humble belt and tensioner.

Modern belts and tensioners can last many hundreds of thousands of kilometres, which is extraordinary when you think of how many billions of times the average belt would go around its pulleys in a lifetime, and how much heat is involved with a modern engine.

But an expert worth listening to recommends replacing the tensioner as a matter of course every 200,000 kilometres or so.

That’s the milestone he reached before breaking down because of a failed tensioner in the middle of Australia a couple of years back; and the milestone he’s recently used to replace a tensioner even though it appeared to be fine.

Wayne ‘Wally’ Cox is a former winner of the Australian Trucking Association’s Craig Roseneder Award for technical and maintenance excellence in the workshop.

So as a driver he was able to get himself out of trouble when the tensioner died, but he wouldn’t have been able to do that if he wasn’t following his normal practice of carrying a spare belt, tensioner and idlers.

He recommends the same practice for the average truck driver, even though they wouldn’t have the tools and/or capability to change a belt system component themselves.

At least if drivers carry spares, there is a reasonable chance there will be a local mechanically-minded person who can get them out of trouble, Cox reckons.

He says for the sake of just a few hundred bucks, carrying a spare belt system in the toolbox is a great investment, saving not only a lot of money in avoiding a rescue mission, but possibly days of lost time and embarrassment with customers as well.

|

|

Truck driver and mechanic Wayne Cox recommends erring on the side of caution when it comes to belts and tensioners.

|

“The initial outlay is nothing compared with the downtime and the cost,” Cox advises truck owners.

Cox always carries a spare serpentine belt, worth about $50, so-called because they snake around a series of pulleys like a serpent.

The serpentine on a modern truck might power the fan, alternator, power steering, water pump and air conditioning all at once. That saves a lot of space in the engine area.

Serpentine belts – also known as “micro V” belts – consist of ribs which sit on multiple pulley grooves. A truck belt might have anywhere from six to 12 ribs.

Wally Cox rates them as superior to the older “V” belts for individual pulleys, which have rows of cogs in the shape of inverted Vs running across the belt, matching to the V pattern on their pulleys and making them flexible.

Cox believes the serpentines have better life, run truer, dissipate heat better, and have better grip. To that list you could probably add that they are quieter.

He always makes sure to carry a spare tensioner and idlers, as well as belt: “They normally fail before the belts in my experience.”

That view isn’t necessarily shared by the belt drive component manufacturers.

|

|

Stressful life: a Gates belt tensioner.

|

Good and bad news

One of the most prominent brands of belts and tensioners globally – along with Dayco, for example – is Gates Corporation, headquartered in the United States and, like Dayco, in business for more than a century.

Gates says serpentine belts started to make their mark in the heavy duty market in the early 1990s.

But there has been a change in serpentine belt technology “which most technicians have not yet become used to”.

That change is in what the belts are made of.

The material has changed from Neoprene to EPDM – a synthetic rubber mostly made of ethylene and propylene – which Gates says is much longer lasting but rarely shows visual symptoms of wear.

That’s why you can no longer rely on a visual inspection and traditional signs of belt wear – including cracking; chunk out; material loss; fraying; uneven wear; shiny spots from heat/slipping; and squealing.

These symptoms could start appearing in the older Neoprene belts at just 80,000 km.

Gates says that as EPDM belts age, they gradually lose rubber material, similar to how a tyre wears out.

“Over a period of 160,000 km, a belt can lose up to 10 per cent of its rib material. While this may not seem like a lot, the consequences can be significant.”

|

|

Using a Gates wear gauge on a serpentine belt.

|

To help identify worn EPDM serpentine belts Gates has developed tools as simple as a small orange plastic gauge and as sophisticated as digital imaging technology.

Gates says that replacing just the belt “only solves half the problem”.

“Loss of tension in the accessory belt drive system is the number one cause of noise and is often overlooked,” the company says.

“Overlooking the source of the problem in the accessory belt drive system may result in the failure of components within the system.

“Both belt slip and loss of tension create heat which can result in premature failure of components such as pulleys and bearings as well as false codes which will result in customer comebacks.

“Often, loss of tension is caused by a failing tensioner, which usually does not get replaced.

“A failed belt or tensioner will still turn the pulleys but will not effectively transmit power.”

Gates Corporation says proper alignment before installing a new belt is important; as is keeping pulleys clear of dirt and grease.

|

|

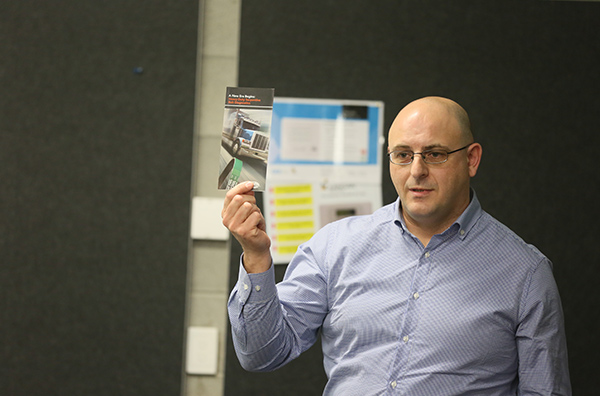

Gates Corporation’s Gerry Rech talking belts and tensioners at last year’s ATA/Paccar Technical and Maintenance Conference. The next TMC is on next month. Picture by Marcel Voestermans.

|

As Gerry Rech, state manager for Victoria and Tasmania for Gates, tells TradeTrucks: “You don’t want a truck breaking down on the Hume Highway at four in the morning because at the last service the problem wasn’t identified.”

Rech has been carrying out a roadshow of truck and bus workshops as part of an ongoing Gates education program.

“Technology has changed, and the more people understand the better,” he says.