After hearing good stories about the Wettenhalls Group’s LNG-powered Kenworth K108, Gary Worrall travelled to Geelong to check it out for himself

With stories aplenty, including quite a few in the pages of ATN, about the need to research and introduce alternative fuels to supplant or replace crude-based diesel, when the chance came to have a drive in the Wettenhalls Westport-powered K108 Kenworth, it was too good to refuse.

Based at Colac in regional Victoria, the gas-fired Kenworth travels between the Fonterra dairy processing plants and the cold stores in Laverton, on Melbourne’s western fringe.

After a briefing from Wettenhalls General Manager Chris Garschagen, it was off to a cold and wet Geelong to meet up with regular driver Matt Egan, and then to head towards an even colder and greyer Laverton to drop off a full load of butter and yoghurt, before reloading and heading back ‘out west’.

Garschagen says the LNG-fuelled Kenworth has received nothing but praise from customers and staff alike. And while it did cost more to purchase, the company is confident they will see a return on their investment during the truck’s normal lifecycle.

The only real difference between a ‘traditional’ prime mover and the Wettenhalls Westport High Pressure Direct Injection GX-equipped version is the thirst for liquid natural gas (LNG) that necessitates a refuelling stop every shift to keep the tanks topped up.

Like most large fleets, Wettenhalls keeps the Kenworth on the road as much as possible, working to the adage that a truck is not earning money sitting in a yard.

A second driver works the afternoon and night shifts.

Engine

The donor Cummins ISX has lost very little in the conversion to run on LNG, with power outputs of up to 580hp (432kW) and 1,850lb/ft (2,500Nm) of torque, compared with 600hp (447kW) and 2,250lb/ft (3,050Nm) for the diesel burner.

Performance

On first inspection, the Westport-engined K108 is virtually indistinguishable from any other K108 roaming the nation’s highways, in itself a testament to the work of not just Westport, but Kenworth in ensuring the truck does not stand out in a crowd.

The only real difference is the central gas tank, mounted transversely between the cab and A-Trailer, while the side-mounted tanks have prominent but not overbearing LNG decals to remind onlookers and emergency services they are looking at something special.

After a bad night, caused by a less than perfect dinner the night before, I opted to take the passenger seat initially, with the chance to drive later if my stomach improved sufficiently.

At this point I remembered my reluctance to board K108s, due to the poorly designed entry that requires both driver and passenger to first open the door, then scale the ladder at the rear, before working forwards to swing in through the door opening.

Kenworth assures us this has been addressed in the 2011 model range, due for public release later this month, but for now, the old method is still the only way in and out.

With the engine fired up, the first thing that comes to mind is the quieter idle compared with a Cummins-powered Kenworth. By comparison this has a slightly higher pitch and lower overall volume, which is a good start.

Pulling out of the yard, driver Matt Egan headed for the freeway and our first delivery, to the Oxfords cold store at Laverton, where the bulk of the load would be dropped.

Egan admits to using one gear lower than he is used to for acceleration, although with just over 30,000km on the engine, it is possible the difference will close up as the engine is run in.

“You do feel a little down on power but not much, but there are advantages, it is certainly quieter than a standard Cummins motor,” Egan says.

Despite the slight drop in power with the gas conversion, the real story is that in traffic the Westport engine can more than hold its own with the trucks around it; this is no mean feat when it is remembered that with a full load on the trailers the gross weight is around 69 tonnes.

After a short while on the freeway, Egan’s comment about the quieter running engine starts to make sense. In the past, having conversations across the cab of a Cummins-powered truck could involve the use of sign language and smoke signals. In this truck, the conversation flows easily from one side to the other.

Despite his relatively young age at 33, Egan, a native ‘town boy’ from Colac, has already driven a wide variety of trucks including Kenworths and International Eagles, having spent his entire career with Wettenhalls, working his way up from yard hand to driver, first in rigids and then eventually B-Doubles.

With a stint in the company’s line-haul division behind him, Egan says the short-haul driving suits him perfectly, ensuring he is at home every night and able to sleep in his own bed, although he says the K108’s sleeper has come in handy at some of the busier delivery centres, providing somewhere to have a rest while he waits to be loaded or unloaded.

After arriving at the first cold store, Egan says it is time for a break while we are relieved of the bulk of our load, with the B-Trailer backed into the receiving dock for fast processing with the insulated curtain-side pulled back for access by the fork lift drivers.

When the time comes to move on, the Kenworth becomes a different beast, with big chunk of weight off the axles, suddenly the traffic is working to keep up with us, Egan swiftly working through the gears to bring the truck up to speed and then hold it there.

Now, it is virtually impossible to tell the Wettenhalls rig from any other truck, except for the softer engine noise. That fact does not go unnoticed during deliveries, with forklift operators happy to discuss how much they enjoy working around the LNG truck, due to the cleaner exhaust and lower engine noise.

After completing the scheduled drops and reloading with lactose for the processing plants back in Cobden, it is time to top the tanks up with gas, which necessitates a short detour into Deer Park.

Unlike a regular refuelling stop with pumps all around and often two going at once to speed the process, the Deer Park LNG facility is, well, different.

First of all, Egan goes to the equipment locker and dons what looks suspiciously like a butcher’s apron, followed by a clear face shield and a rather thick pair of gloves.

While I am harbouring thoughts of having hitched a ride with a serial killer, he reassures me this is the protective garb that keeps him safe from any accidental gas spills.

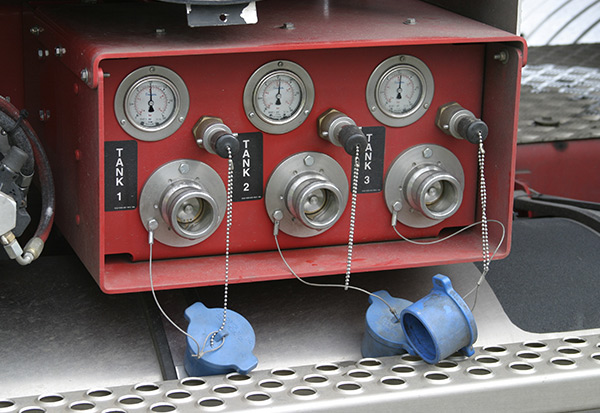

The next step is to equalise the pressures and temperature in the three onboard gas tanks, before trying to refill them from the storage facility, where the natural gas is held in liquid form at a bracing -161 degree celsius.

With the tanks ready to go, a process that only takes a few seconds, although it can vary, depending on ambient temperature and other factors, Egan looks like a racing car mechanic, except for the butcher’s apron and face shield, as he pushes the ‘dry break’ nozzle into the tank to start the filling process.

Due to the extremely low temperature of the fuel, it is easy to pick when the liquid is flowing as ice begins to form on the hose, nozzle and other pump fittings, although it does not affect the flow rate.

With three tanks to fill, Egan just waits for the indicator to tell him the first one is full, before disengaging the nozzle and plugging it into the next one, with the whole process taking less time than it takes to make a cup of coffee in the driver’s lounge.

With the refuelling equipment safely stored back in the lockers and a print-out showing how much gas was discharged it is back into the cab and on our way back to Geelong, with full tanks and laden trailers.

Asking Egan the obvious question – would he have an LNG-powered truck of his own if the chance came up, the response was unequivocal: “Yes, we just need more fuelling points.”

Yet again, as we rumble down the highway, cruising on the legal limit, it is clear the decision to go with LNG looks like being a winner for Wettenhalls.

Verdict

The truck runs faultlessly, with no penalty in terms of payload, and is earning plenty of ‘greenie points’ for the company with its customers and the farming communities it runs through every night.

Garschagen gets the last word on the issue, echoing Egan’s sentiments about the need for more filling stations.

“We are actively considering the expansion of our LNG fleet.

“But we need more places to refuel, a refuelling network would make interstate shuttles feasible,” he says.